Efficient production capacity: the machine is equipped with automatic operation function, which can produce large quantities of popcorn buckets in a short period of time, greatly improving the production efficiency and adapting to the needs of large-scale production.

Stable product quality: the machine is equipped with advanced technology and precision control system, which can ensure the stable quality and uniform size of the popcorn buckets produced, which is suitable for all kinds of entertainment activities or retail market.

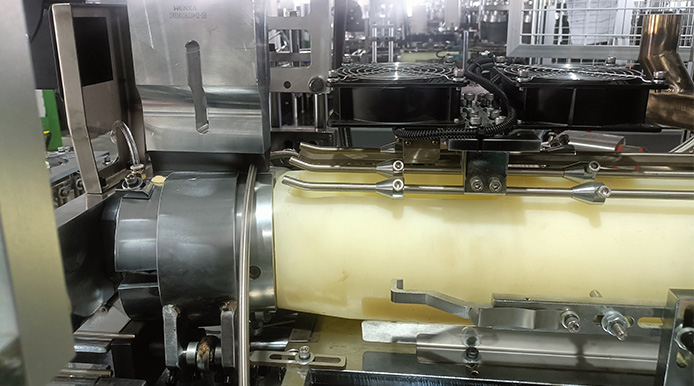

YB-WJ200 Fully automatic paper bowl forming machine, stable operation speed of 70-80PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heatingsystem for bottom sealing.

Paper Bowl: 10oz-100 oz

Production Capacity: 70-80 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

Compressive strength: simulate stacking transport (e.g. 500 paper cups stacked for 24 hours without deformation).

Leakage test: 95℃ hot water standing for 30 minutes without leakage (GB/T 27590-2011 standard).

Migration test: Detect the amount of heavy metals, plasticisers and other leaching (in line with EU 10/2011).

Round bowls: sauce cups (5oz) → fast food bowls (12-24oz) → salad sharing bowls (32-64oz+)

Square Bowls: Lunch Boxes (750-1500ml) → Gift Grade Premium Food Boxes

Special function bowls: anti-scald coffee bowl (with waistline), leak-proof soup bowl (thickened and sealed edge), stackable dessert bowl

Reinforced sealing at all four corners

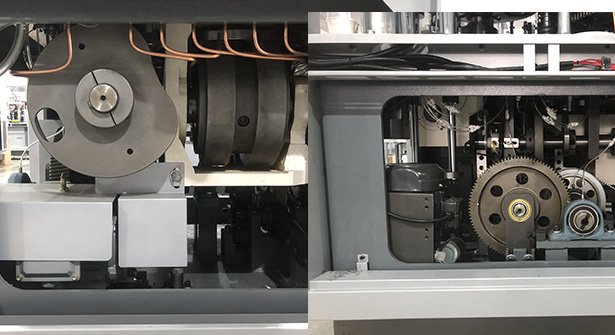

Precise corner folding mechanism

PLA laminated paper, PBAT coated paper, fluorine-free greaseproof paper, etc. (Grammage 190-350gsm).