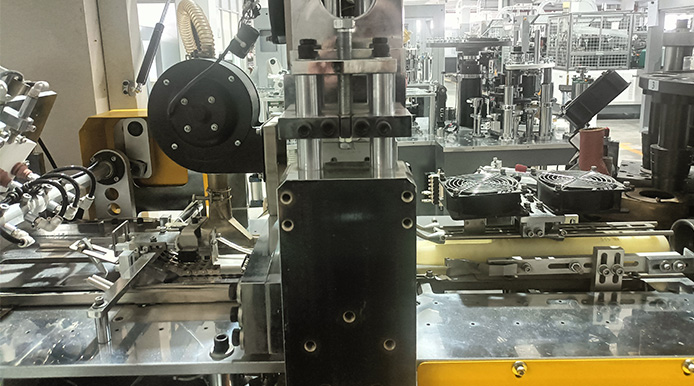

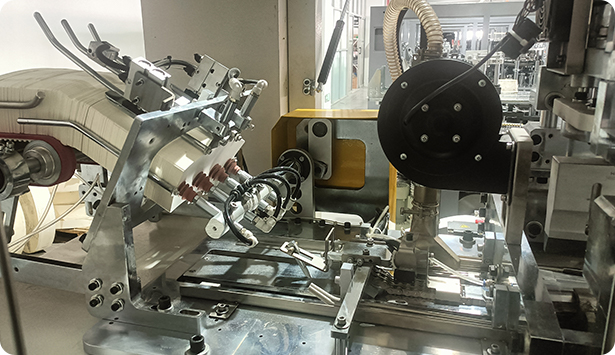

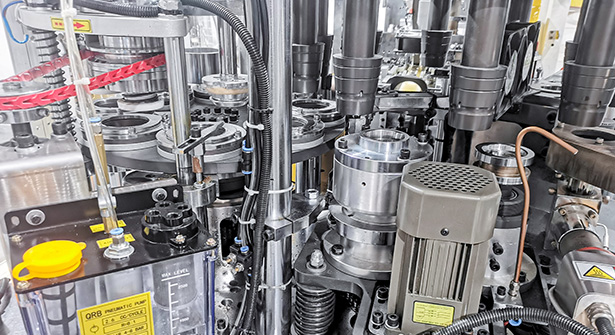

Multi-station simultaneous moulding

High-speed continuous paper supply

YB-SF660 fully servo paper cup forming machine is equipped with a servo system that can precisely control the movement of each component the paper cup machine, ensuring fast response times and high speeds, meeting the requirements for high.quality packaging and use.

Paper Cup Specification: 3-16 Oz

Production Speed: 180-210 pcs/min

Paper Cup Material: 150-350 g/m²

YB-S180 High-speed paper cup forming machine has the advantages of high performance,high efficiency and high quality;The overall steel plate body and the oil-draining lubrication system ensure the long-term normal and stable operation of the equipment;

Paper Cup Specification: 2-16 Oz

Production Speed: 120-150 pcs/min

Paper Cup Material: 150-350 g/m²

YB-S122 High-speed paper cup forming machine has the advantages of high performance,high efficiency and high quality; The overall steel plate body and the oil-draining lubrication system ensure the long-term normal and stable operation of the equipment;

Paper Cup Specification: 1.5-10 Oz

Production Speed: 120-140 pcs/min

Paper Cup Material: 150-350 g/m²

YB-S100 automatic high speed paper cup forming machine,the paper feeding process is smooth, to the maximum speed of 130 per minute,stable running speed of 100-110 according to the paper material.

Paper Cup Specification: 2-16 Oz

Production Speed: 100-110 pcs/min

Paper Cup Material: 150-350 g/m²

YB-S90 medium speed paper cup forming machine is improved on the existing S100 specially designed for produce small size cups which below 9Oz stable speed is 100-110/min.

Paper Cup Specification: 2-9 Oz

Production Speed: 100 pcs/min

Paper Cup Material: 150-350 g/m²

YB-12 automatic medium paper cup machine, has the advantages of high performance, high efficiency, high quality, stable speed 80-90 per minute, using open CAM and gear transmision each station to achieve accurate, automatic lubrication.

Paper Cup Specification: 1.5-16 Oz

Production Speed: 80-90 pcs/min

Paper Cup Material: 150-350 g/m²

YB-9 intelligent medium speed paper cup molding machine has the advantages of high performance, high efficiency and high quality; The integral steel plate body and the lubrication system of the oil type ensure the long-term normal and stable operation of the equipment.

Paper Cup Specification: 1.5-16 Oz

Production Speed: 75-85 pcs/min

Paper Cup Material: 150-350 g/m²

YB-WT80 middle speed double wall paper bowl forming machine, with photoelectric detection fault alarm and other functions, with paper cup machine, paper bowl machine configuration,through automatic paper feeding, ultrasonic welding sealing (adhesive sleeve wall)

Paper Cup Specification: 2-16 Oz

Production Speed: 90-100 pcs/min

Paper Cup Material: 150-350 g/m²

YB-WT160 high-speed double wall paper cup forming machine is a multi-station high speed paper cup making equipment, mainly utilized for making the outer-sleeve of paper cups and paper bowls.

Paper Cup Specification: 2-16 Oz

Production Speed: 90-100 pcs/min

Paper Cup Material: 150-350 g/m²

Reinforced bottom:

Increase the weight-bearing capacity (some paper bowls can bear more than 1kg).

Rolled edge reinforcement:

Multi-layer rolled edge technology on the mouth of the cup to prevent deformation or leakage.

Full category coverage: standard single-layer cups (3oz-24oz), double-layer insulated cups (8oz-16oz), cups with handles, square cups, ice cream cups and special conical cups.

Special adaption: support PE/PLA lamination paper, aluminum foil composite paper, biodegradable materials, grammage range 180-400gsm.

Scenario extension: coffee cups with anti-scald design, milk tea cups with high sealing, salad cups with anti-pressure structure can be customized.

In-line production reduces direct labor costs by 70%+ and OEE (Overall Equipment Effectiveness) ≥ 85%.

Online quality control system

Paste handle machine integration module

Intelligent Packaging System