Accurately matches the full size range from mini sauce cups (5oz) to jumbo sharing bowls (64oz+), from classic round to square lunch boxes.

Easy handling of light-weight thin papers (180gsm) to ultra-thick/composite specialty papers (450gsm+).

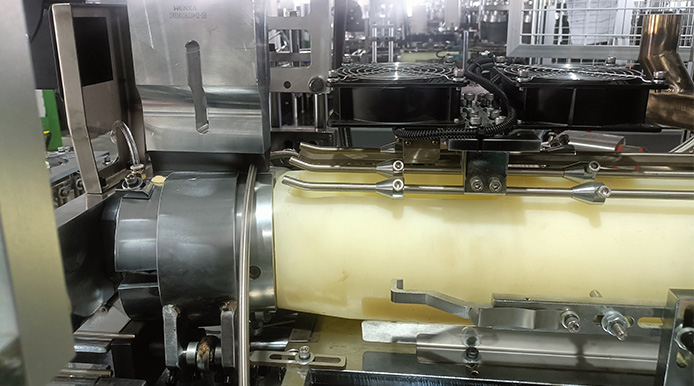

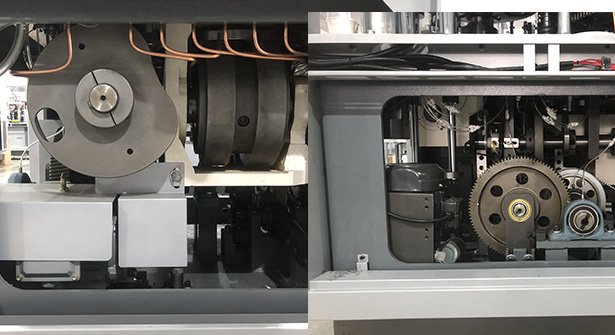

YB-WJ70 Fully automatic paper bowl forming machine, stable operation speed of 70-80PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heatingsystem for bottom sealing.

Paper Bowl: 7oz-60oz

Production Capacity: 65-80 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

YB-WJ150 Fully automatic paper bowl forming machine, stable operation speed of 70-80 PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heating system for bottom sealing.

Paper Bowl: 7oz-80oz

Production Capacity: 70-80 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

YB-WJ200 Fully automatic paper bowl forming machine, stable operation speed of 70-80PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heatingsystem for bottom sealing.

Paper Bowl: 10oz-100 oz

Production Capacity: 70-80 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

YB-TJ2000 Fully automatic paper bowl forming machine, stable operation speed of 50-70PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heatingsystem for bottom sealing.

Paper Bowl: 10oz-100oz

Production Capacity: 50-70 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

Compressive strength: simulate stacking transport (e.g. 500 paper cups stacked for 24 hours without deformation).

Leakage test: 95℃ hot water standing for 30 minutes without leakage (GB/T 27590-2011 standard).

Migration test: Detect the amount of heavy metals, plasticisers and other leaching (in line with EU 10/2011).

Round bowls: sauce cups (5oz) → fast food bowls (12-24oz) → salad sharing bowls (32-64oz+)

Square Bowls: Lunch Boxes (750-1500ml) → Gift Grade Premium Food Boxes

Special function bowls: anti-scald coffee bowl (with waistline), leak-proof soup bowl (thickened and sealed edge), stackable dessert bowl

Reinforced sealing at all four corners

Precise corner folding mechanism

PLA laminated paper, PBAT coated paper, fluorine-free greaseproof paper, etc. (Grammage 190-350gsm).