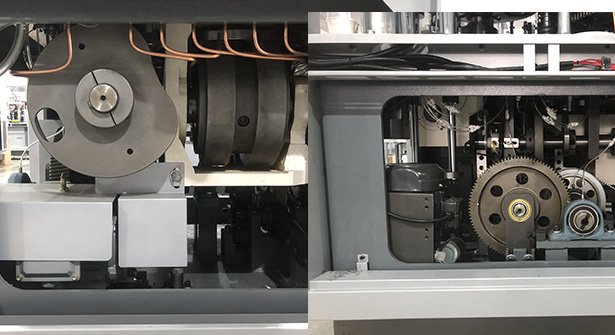

Reliability: YB-W70 intelligent medium-speed paper bowl forming machine has the advantages of high performance, high efficiency and high quality; The integral steel body and the auto oil lubrication system ensure long-term normal and stable operation of the machine;

Energy efficient: The advanced high-precision open cam drive and gear drive make it more accurate and stable; Servo tracking bottom paper feeding locks the size of the bottom paper , which effectively saves raw materials;

Humanizing: The man-machine interface PLC system controls the long-term stable operation of the whole machine;

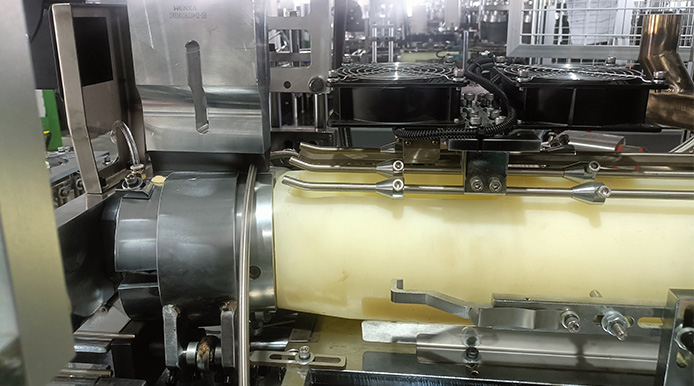

YB-WJ70 Fully automatic paper bowl forming machine, stable operation speed of 70-80PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heatingsystem for bottom sealing.

Paper Bowl: 7oz-60oz

Production Capacity: 65-80 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

YB-WJ150 Fully automatic paper bowl forming machine, stable operation speed of 70-80 PCS per minute. The machine uses ultrasonic waves to seal the bowl. Hot air heating system for bottom sealing.

Paper Bowl: 7oz-80oz

Production Capacity: 70-80 pcs/min

Paper Specification: 150-350 GSM single/double PE coated paper

Compressive strength: simulate stacking transport (e.g. 500 paper cups stacked for 24 hours without deformation).

Leakage test: 95℃ hot water standing for 30 minutes without leakage (GB/T 27590-2011 standard).

Migration test: Detect the amount of heavy metals, plasticisers and other leaching (in line with EU 10/2011).