Intelligent docking with the output of front-end paper bowl machine, realizing the automation of the whole process from the finished bowl to the completion of packaging.

Servo drive and vision positioning technology, accurate gripping, counting, bagging/boxing.

The fully automatic vertical paper cup packaging machine is developed and designed according to market demand, mainly for the integrated molding of paper cup packaging and labeling, with small, saving space, flexible movement and other main features.

Cup Diameter: Ø65-Ø100, Ø100-Ø145

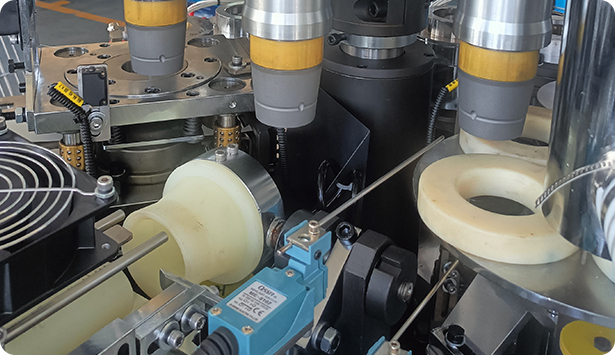

Packaging Film Material: OPP/PE/PP/POF

Packaging Film Thickness: 15-30Um

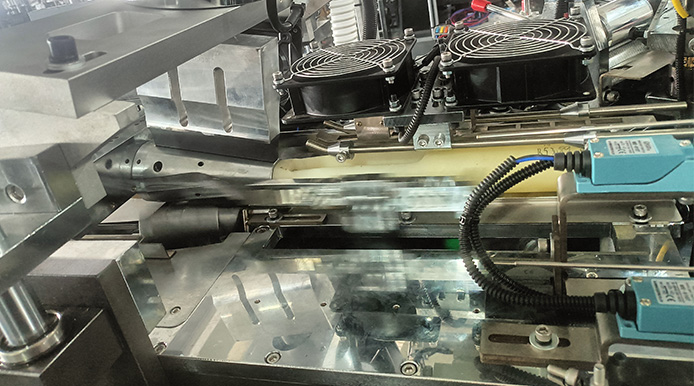

YB-520B is equipped with 4 independent motor control (feeding mechanism adopts servo motor, cup feeding, cup discharging, waste collection)

Cup Diameter: Ø65-Ø100, Ø100-Ø145

Packaging Film Material: OPP/PE/PP/POF

Packaging Film Thickness: 15-30Um

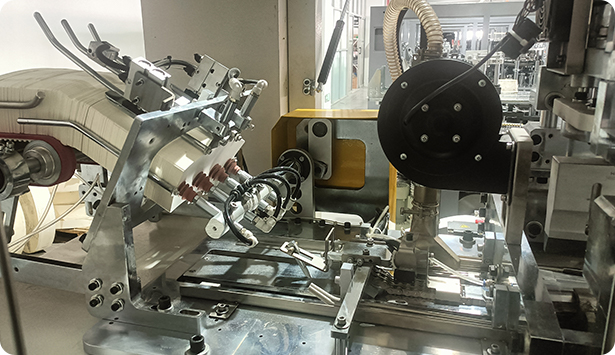

YB-NBJ medium speed handle forming machine is a new type of paper cup machine developed by our company. On the basis of the original paper cup forming machine, it adds the process of automatic cutting handle of roll paper conveying and ultrasonic bonding handle.

Paper Cup Specification: 2-16 Oz

Production Speed: 90-100 pcs/min

Paper Cup Material: 150-350 g/m²

Reinforced bottom:

Increase the weight-bearing capacity (some paper bowls can bear more than 1kg).

Rolled edge reinforcement:

Multi-layer rolled edge technology on the mouth of the cup to prevent deformation or leakage.

Compressive strength: simulate stacking transport (e.g. 500 paper cups stacked for 24 hours without deformation).

Leakage test: 95℃ hot water standing for 30 minutes without leakage (GB/T 27590-2011 standard).

Migration test: Detect the amount of heavy metals, plasticisers and other leaching (in line with EU 10/2011).

PE lamination paper tape (width 10-25mm)

Transparent/color PET sheet (thickness 0.2-0.8mm)

Rattan-like composite material (customizable curved surface lamination)

PLC of packaging machine receives real-time output signal from host machine and adjusts speed dynamically (matching speed 50-250 packages/minute).

Vision positioning system automatically corrects cup/bowl attitude to ensure bagging accuracy ≤ 0.3mm offset.

48 hours emergency response, standard spare parts arrive in 3-5 days.