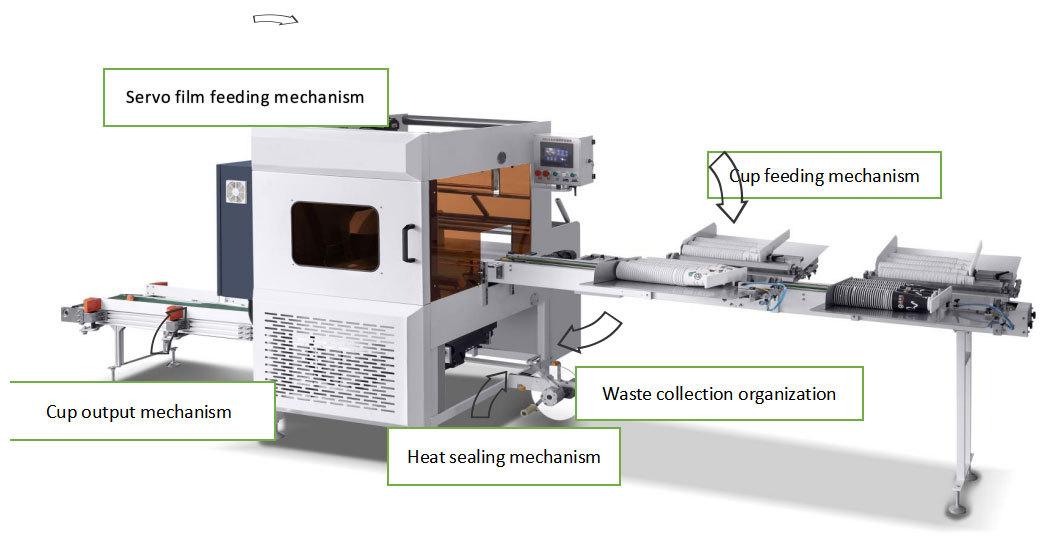

YB-520B is equipped with 4 independent motor control (feeding mechanism adopts servo motor, cup feeding, cup discharging, waste collection)

Cup Diameter: Ø65-Ø100, Ø100-Ø145

Packaging Film Material: OPP/PE/PP/POF

Packaging Film Thickness: 15-30Um

YB-520B is equipped with 4 independent motor control (feeding mechanism adopts servo motor, cup feeding, cup discharging, waste collection), air defense bag function: start with material, stop without material, save packaging film, prevent not timely feeding, waste packaging film, equipment air pressure is insufficient automatic stop alarm to reduce material waste.

Cup feeding: after the paper cup is counted by the cup counting frame, it falls down and slides onto the cup table. After the optical eye detects a cup, the cup turning mechanism pours the paper cup on the rope and send it to the top of the heat sealing splint;

Film feeding: when the optical eye detects a cup, it sends a pulse to the servo driver after being recognized by the PLC program, and sends out the corresponding length film according to the different caliber of the cup;

Heat sealing: the hot air splint opens, the cup down, the splint closes, and the heat sealing knife heat seals the film to complete the bag sealing process;

Cup output: the sealed cup drops onto the rear conveyor board, and cups of different specifications are dropped into the box from the corresponding cup outlet according to the memory function of PLC program to complete cup collection.

|

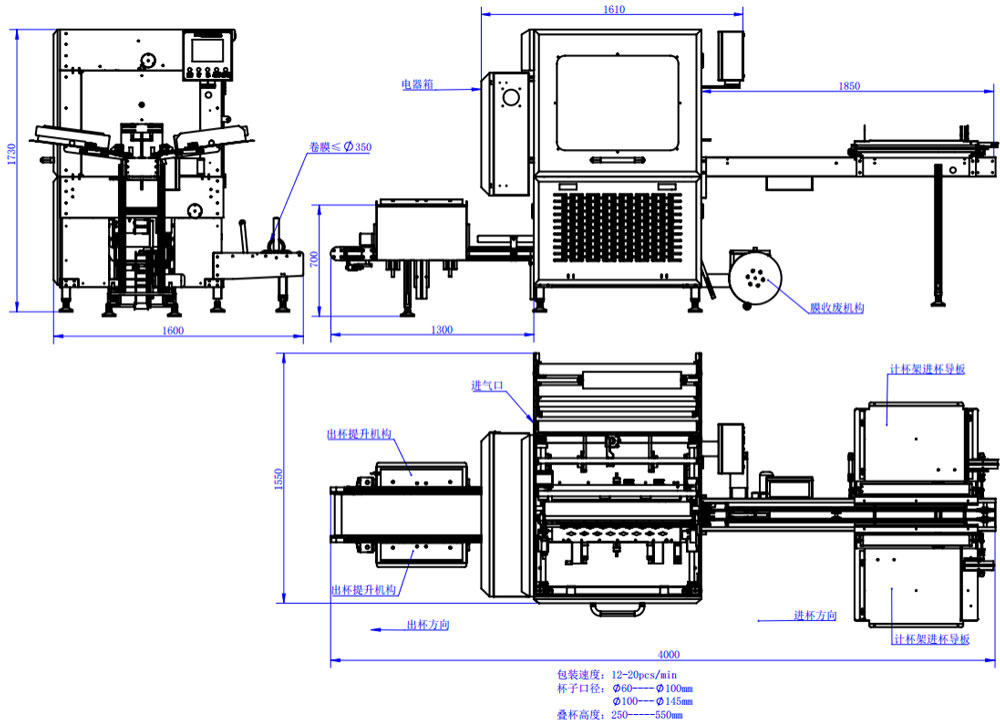

Model |

YB-520B (single station) |

|

Speed |

10-20 bag/min (The characteristics of products and membranes may affect the output of the machine) |

|

Cup bottom size |

Ø65-Ø100、Ø100-Ø145 |

|

Package height |

250----550mm |

|

Material of packing film |

OPP PE PP POF |

|

Thickness of packing film |

15----30um |

|

Total power |

2.8KW |

|

Electrical power |

220V 50HZ |

|

Air supply |

≥0.5 Mpa |

|

Weight |

800kg |

|

Machinery size |

6000*1600*1730mm |

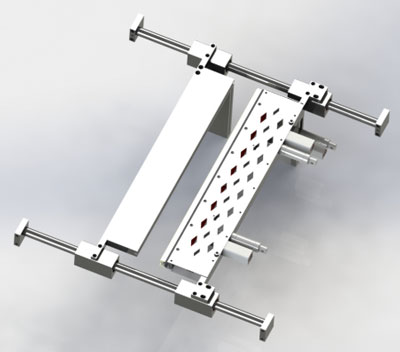

The use of mechanical and pneumatic execution makes the incision more firm and beautiful. Compared with other supplier’s machines, the noise is less, the machine vibration is less, and the adjustment is more convenient. In addition, the cutter uses special materials and quenching process to make the cutter more durable, and PE, OPP, PP, POF films and other types of packaging films can be effectively used. And the cutting knife crosses the iron boiling dragon, which makes the packaging machine effectively prevent the film from sticking when running, and it is more convenient to clean.

The design of servo motor film feeding mechanism makes the film feeding more accurate. When it is produced online with multiple units of paper cup machines, the film length can be set in groups, which is more suitable for paper cups of different sizes and packaging sizes and saves film materials.

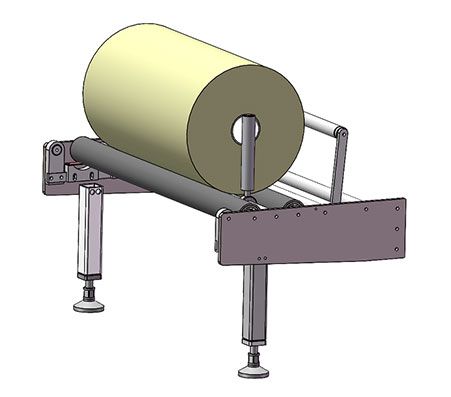

The film supporting mechanism adopts the form of floor support, which is more convenient and faster than traditional machines for threading and loading film. It can bear the weight of film and has less restrictions on the size of film materials, and can be loaded with larger packaging film.

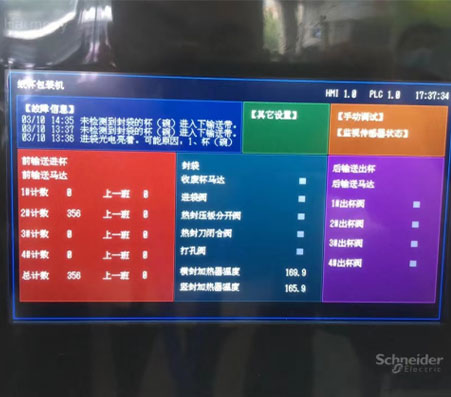

The imported international brand PLC programmable controller and touch human-machine interface make the operation easier.

• 4 independent motor control (servo motor is used for the feeding mechanism, which can feed, discharge and collect waste)

• Motion controller for fast response to various commands

• Precise positioning of products

• Independent temperature control module controls the temperature, and the heating is more stable and uniform

• 304 stainless steel is used for the part in contact with the product

• All of the electrical components used international brands

• Anti empty bag function: start with material and stop without material, save packaging film, and prevent untimely discharge and waste of packaging film

• One machine can produce different specifications and sizes of different paper cup machines online

• Automatic shutdown alarm for insufficient air pressure of equipment to reduce material waste

• It has cooperated with domestic first-line brand paper cup manufacturers for many years, and has cooperated with many domestic paper cup manufacturers to make users feel more at ease and have stable and reliable quality.

Maintenance of Horizontal Packaging Machine should be carried out in strict compliance with the maintenance guidance.

1. Every component should be cleaned up carefully.

2. For sanitation and cleanliness, a fixed schedule should be maintained to clean and wipe the machine. Greasy dirt should be removed from the paper, die and roller.

The machine must be kept from paper scraps, dust, plastic rolling, etc.

3. Glycerol can be used to lubricate the entire machine.

1. We offer a one-year warranty for the Horizontal Packaging Machine from the shipment date.

2. The warranty does not cover normally worn components.

3. We will not be responsible for any damage caused by misusing, improper handling, negligent maintenance, intentional injury or other damages.