YB-SF660 fully servo paper cup forming machine is equipped with a servo system that can precisely control the movement of each component the paper cup machine, ensuring fast response times and high speeds, meeting the requirements for high.quality packaging and use.

Paper Cup Specification: 3-16 Oz

Production Speed: 180-210 pcs/min

Paper Cup Material: 150-350 g/m²

The servo paper cup machine has high stability and reliability,which can ensure long-term continuous operation of the equipment No malfunctions or shutdowns occur, reducing equipment maintenance time and production interruptions One step improved production efficiency.

Use PLC programmable logic controller High reliability, easy and flexible programming, powerful functionality, and maintenance Low maintenance cost, good data processing capability, equipped with fault diagnosis function. When the equipment malfunctions being able to display fault information in a timely and accurate manner, facilitating maintenance personnel to quickly locate and trouble shoot faults.

|

Model |

SF660 |

|

Paper Cups |

3oz -16oz |

|

Specifications

|

(85-450ml) (mold exchangeable) |

|

Top: 45-100mm |

|

|

Height: 60-135mm |

|

|

Bottom: 45-80mm |

|

|

Paper Specification |

150-350 GSM single/double PE coated paper |

|

Production Capacity |

180-210 pcs/min |

|

Voltage |

220V/380V 50HZ 3Phases |

|

Average Power |

17KW |

|

Air Supply Requirement |

Air pressure:0.4 Mpa Air out-put:0.6cbm/min |

|

Total Weight |

3000KG |

|

Dimensions |

2350x1560x2050mm |

1. The SF660 Fully Servo Motor Driven paper cup forming machine also applies many well designed techniques and devices: spray lubrication is mainly applied to decrease the abrasion of components; the imported heater is utilized for sealing cup body and bottom; silicon oil flow is precisely controlled by an electromagnetic valve. This high-yield paper cup forming machine conducts two forming steps, rotating curling and heating& forming. By doing so, it produces cups with high strength and uniform size.

2. When it comes to PLC control, by utilizing a photoelectric sensor and servo control feeder, the paper cup forming machine ensures a high speed and stable operation and achieves a significant decrease in labor cost. In addition, this automated paper cup forming machine will automatically shut down when any malfunction is detected.

3. The paper cup forming machine with the assistance of a CCD image detecting system, cups that are broken, stained or defective can be picked out. This effective system achieves no manual intervention and reduces secondary contamination of product.

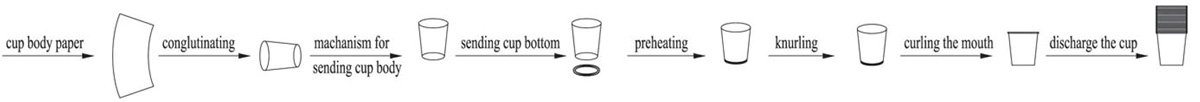

4. This kind of paper cup forming machine equals to one piece of equipment that integrates all cup making procedures, including paper feeding, sealing, cup bottom feeding, heating, knurling, cup-mouth curling, discharging, testing and counting. SF660 Fully Servo Motor Driven Paper Cup Machine is an ideal choice for making cups of 50-135mm high.

• High dimensional accuracy , accurate position accuracy . The servo system can precisely control the movement of each part of the paper cup machine to meet the requirements of high quality packaging and use.

• High-speed servo motor with fast response speed and high speed.

• Servo paper cup machine has high stability and reliability, which can ensure the continuous operation of the equipment for a long time without failure or shutdown, reduce the maintenance time and production interruption of the equipment, and further improve the production efficiency.

• The servo motor can precisely adjust the power output according to the actual demand during operation, avoiding the waste of energy . It reduces the production cost of the enterprise.

• Servo motor operation noise is low, reducing the noise pollution of the production environment , providing a relatively quiet working environment for workers.

• The structure of the servo paper cup machine is relatively simple , and the connection and disassembly between the components are more convenient , which is convenient for the daily maintenance and maintenance of the equipment.

• The servo system has the function of self-diagnosis and alarm , when the equipment fails , it can display the fault information promptly and accurately , which is convenient for maintenance personnel to quickly locate and troubleshoot the fault , and reduce the maintenance time and cost of the equipment.

• Use PLC programmable logic controller. High reliability , easy programming . Strong flexibility. Powerful function , low maintenance cost . Good data processing ability.

• Can produce hot and cold paper cups. Widely used in catering industry .

Maintenance of SF660Fully Servo Motor Driven Paper Cup Forming Machine should be carried out in strict compliance with the maintenance guidance.

1. Every component should be cleaned up carefully.

2. For sanitation and cleanliness, a fixed schedule should be maintained to clean and wipe the machine. Greasy dirt should be removed from the paper, die and roller. The machine must be kept from paper scraps, dust, plastic rolling, etc.

3. Glycerol can be used to lubricate the entire machine.

1. We offer a one-year warranty for the SF660 Fully Servo Motor Driven Paper Cup Forming Machine from the shipment date.

2. The warranty does not cover normally worn components.

3. We will not be responsible for any damage caused by misusing, improper handling, negligent maintenance, intentional injury or other damages.

• 24/7 Customer Support

Provide multi-channel (phone, live chat, email, app) instant technical support to ensure customer issues are addressed immediately.

Offer multilingual services to meet the needs of global customers.

• Priority Response Mechanism

Classify priorities based on urgency (e.g., 2-hour response for equipment breakdowns, 24-hour response for non-critical issues).

Provide remote diagnostics via IoT technology for real-time monitoring and early detection of potential issues.

• Spare Parts Supply Chain Management

Establish regional spare parts centers to ensure fast replacement of commonly used components.

Offer replacement equipment or backup machines (for critical devices) to minimize downtime losses.