Intelligent docking front-end paper cup/bowl production line, realizing the whole process of operation from single piece finished product→accurate counting→automatic bagging/boxing→sealing/palletizing.

Intelligent consumable control: Equipped with intelligent cutting algorithm and adaptive sealing system to minimize the waste of film/bag/cardboard (material saving rate up to 15%-30%).

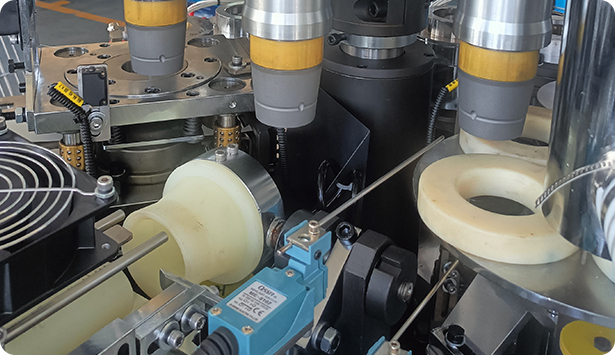

The fully automatic vertical paper cup packaging machine is developed and designed according to market demand, mainly for the integrated molding of paper cup packaging and labeling, with small, saving space, flexible movement and other main features.

Cup Diameter: Ø65-Ø100, Ø100-Ø145

Packaging Film Material: OPP/PE/PP/POF

Packaging Film Thickness: 15-30Um

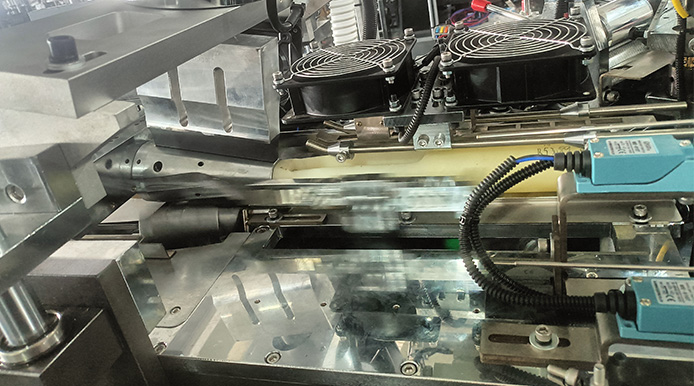

YB-520B is equipped with 4 independent motor control (feeding mechanism adopts servo motor, cup feeding, cup discharging, waste collection)

Cup Diameter: Ø65-Ø100, Ø100-Ø145

Packaging Film Material: OPP/PE/PP/POF

Packaging Film Thickness: 15-30Um

Reinforced bottom:

Increase the weight-bearing capacity (some paper bowls can bear more than 1kg).

Rolled edge reinforcement:

Multi-layer rolled edge technology on the mouth of the cup to prevent deformation or leakage.

Compressive strength: simulate stacking transport (e.g. 500 paper cups stacked for 24 hours without deformation).

Leakage test: 95℃ hot water standing for 30 minutes without leakage (GB/T 27590-2011 standard).

Migration test: Detect the amount of heavy metals, plasticisers and other leaching (in line with EU 10/2011).

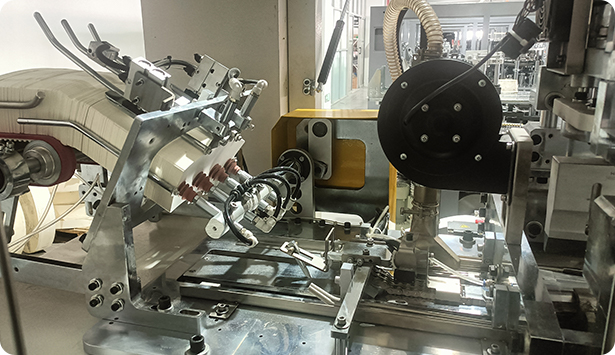

Dynamic vision guidance

Cooperative servo control

Adaptive lamination system

Compatible with all types of containers with a diameter of 50-160mm and a height of 60-220mm.

The display screen is easy to operate.