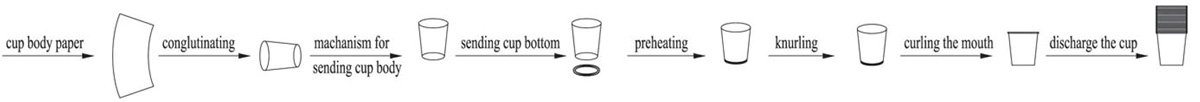

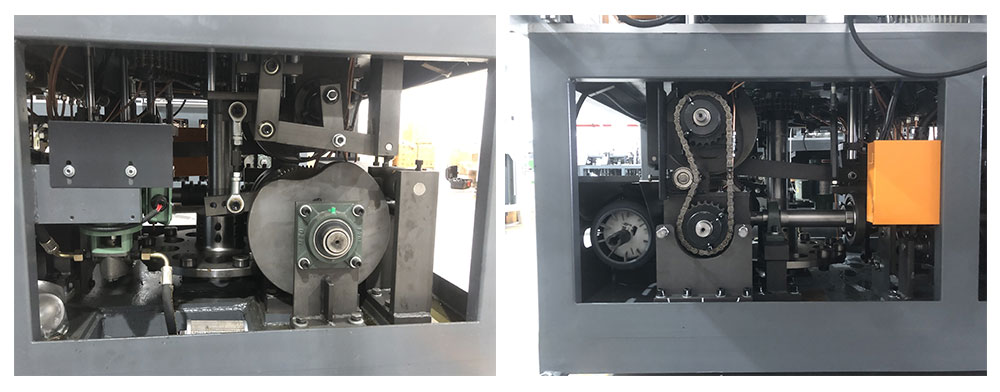

YB-12 automatic medium paper cup machine, has the advantages of high performance, high efficiency, high quality, stable speed 80-90 per minute, using open CAM and gear transmision each station to achieve accurate, automatic lubrication.

Paper Cup Specification: 1.5-16 Oz

Production Speed: 80-90 pcs/min

Paper Cup Material: 150-350 g/m²

YB-12 automatic medium paper cup machine,has the advantages of high performance, high efficiency, high quality, stable speed 80-90 per minute, using open CAM and gear transmission each station to achieve accurate,automatic lubrication.Intelligent servo tracking feed bottom and PLC system.With automatic counting collector,can make single PE and double PE coated paper cups.

|

Model |

YB-12 |

|

Paper Cups |

1.5oz - 16oz |

|

Specifications

|

(40-450ml) (mold exchangeable) |

|

Top: 45-100mm |

|

|

Height: 30-135mm |

|

|

Bottom: 30-72mm |

|

|

Paper Specification |

150-350 GSM single/double PE coated paper |

|

Production Capacity |

80-90 pcs/min |

|

Voltage |

220V/380V 50HZ 3Phases |

|

Average Power |

4 KW |

|

Air Supply Requirement |

Air pressure:0.4 Mpa Air out-put:0.4-0.5 cbm/min ( Air Compressor required ) |

|

Total Weight |

1850KG |

|

Dimensions |

2260 x 1400 x 1980 mm |

• Ultrasonic: The wall sealing take ultrasonic sealing more fast and stable with good product.

• Sensors: Sensor detection throughout the program (sensors control all steps), reducing waste and failure , more reliable and stable.

• Oil circuit system: Prolong the service life of parts, reduce friction losses, and improve machine efficiency.

• Heat dissipation function: Maintain the normal operating temperature of the equipment, extend the production service life, and improve the safety of use.

• Hot air system: The heating speed is fast, the constant temperature is more stable , and the scrap rate is greatly reduced to ensure the normal operation of the equipment.

• Low initial investment: Compared with high-speed multi-disc (multi-station) molding machines, single-disc machines have a simple structure and lower procurement costs, making them suitable for companies with limited budgets or start-up factories.

• Trial-production friendly: Suitable for new product prototyping or small-scale trial production, avoiding waste caused by mold coordination problems in multi-disc machines.

• Low failure rate: The mechanical structure is simple, the operation stability is high, and the downtime caused by multi-station synchronization problems is reduced.

• Reasonable speed: The medium-speed design balances efficiency and quality, and is suitable for small and medium-sized customers with daily production requirements of 10,000~30,000 pieces.

• Uniform heating: The heating system of the single-disc mold (such as bottom hot pressing) is easier to control the temperature, avoiding cup deformation or poor gluing caused by uneven heat distribution in multi-disc machines.

• Typical application scenarios Small and medium-sized paper cup factories, food packaging companies. Customized production that requires frequent changes in cup types (such as promotional cups for events, personalized printing). Emerging markets that are cost-sensitive and have moderate capacity requirements (such as Southeast Asia and Africa).

Maintenance of 12 Intelligent Medium Speed Paper Cup Forming Machine should be carried out in strict compliance with the maintenance guidance.

1. Every component should be cleaned up carefully.

2. For sanitation and cleanliness, a fixed schedule should be maintained to clean and wipe the machine. Greasy dirt should be removed from the paper, die and roller. The machine must be kept from paper scraps, dust, plastic rolling, etc.

3. Glycerol can be used to lubricate the entire machine.

1. We offer a one-year warranty for the 12 Intelligent Medium Speed Paper Cup Forming Machine from the shipment date.

2. The warranty does not cover normally worn components.

3. We will not be responsible for any damage caused by misusing, improper handling, negligent maintenance, intentional injury or other damages.

• 24/7 Customer Support

Provide multi-channel (phone, live chat, email, app) instant technical support to ensure customer issues are addressed immediately.

Offer multilingual services to meet the needs of global customers.

• Priority Response Mechanism

Classify priorities based on urgency (e.g., 2-hour response for equipment breakdowns, 24-hour response for non-critical issues).

Provide remote diagnostics via IoT technology for real-time monitoring and early detection of potential issues.

• Spare Parts Supply Chain Management

Establish regional spare parts centers to ensure fast replacement of commonly used components.

Offer replacement equipment or backup machines (for critical devices) to minimize downtime losses.