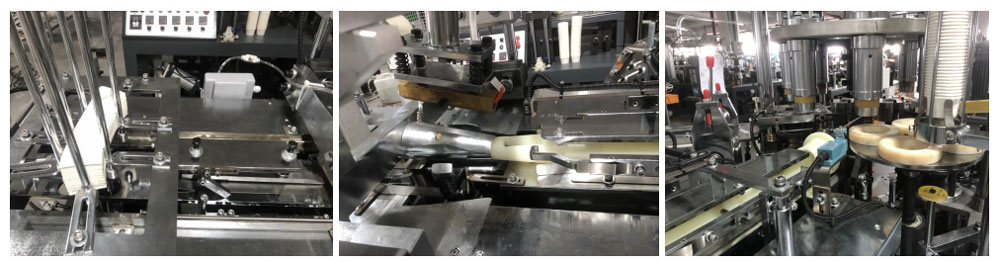

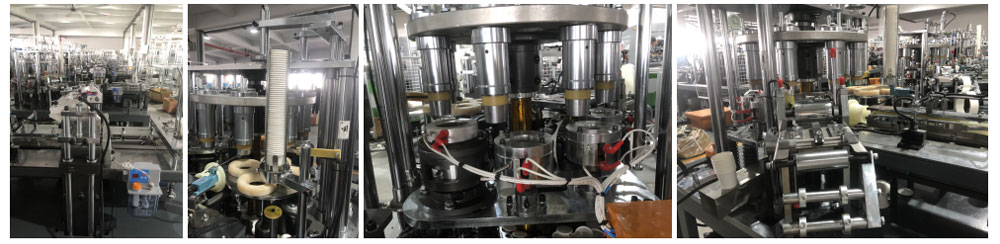

YB-9 intelligent medium speed paper cup molding machine has the advantages of high performance, high efficiency and high quality; The integral steel plate body and the lubrication system of the oil type ensure the long-term normal and stable operation of the equipment.

Paper Cup Specification: 1.5-16 Oz

Production Speed: 75-85 pcs/min

Paper Cup Material: 150-350 g/m²

YB-9 intelligent medium speed paper cup molding machine has the advantages of high performance, high efficiency and high quality; The integral steel plate body and the lubrication system of the oil type ensure the long-term normal and stable operation of the equipment.

Advanced high precision CAM drive and gear drive make each station forming accurate and correct; Servo tracking feed paper to lock the size of the cup bottom paper, effectively save raw materials.

|

Model |

YB-9 |

|

Paper Cups |

1.5oz - 16oz |

|

Specifications

|

(40-450ml) (mold exchangeable) |

|

Top: 40-100mm |

|

|

Height: 30-135mm |

|

|

Bottom: 30-72mm |

|

|

Paper Specification |

150-350 GSM single PE coated paper |

|

Production Capacity |

75-85 pcs/min |

|

Voltage |

220V/380V 50HZ 3Phases |

|

Average Power |

4 KW |

|

Air Supply Requirement |

Air pressure:0.6-0.8 Mpa Air out-put:0.4-0.5 cbm/min |

|

Total Weight |

1750KG |

|

Dimensions |

2200 x 1100 x 1980 mm |

• Multiple paper feeding: Three times of paper feeding, multiple mediation, to avoid unevenness on both sides of the paper cup.

• Photoelectric eye detection: The encoder and the optical eye control the machine at the same time, and a fan-shaped piece is equipped with a cup bottom to avoid waste.Fault alarm, automatic shutdown.

• Automatic fueling system: The machine automatically refuels the positions that need to be refueled through the copper pipe, saving labor.

• Slot wheel: The inside of the machine is connected by a sheave, and the parts are connected more closely. It is not easy to loosen during the operation of the machine.

• Drain the bottom: In the past, the process of feeding the bottom paper to the bottom paper is prone to the bottoming phenomenon. The equipment is used to directly feed the bottom to the bottom, and the bottom is avoided in one step.

• Low failure rate and low maintenance cost.

• Strong patience, high-quality models use high-strength materials, and have a long service life.

• Simple and easy to operate, changing the grinding tool can achieve the production of various sizes of cups.

• The equipment has a small footprint, low operating costs, low energy consumption, simple maintenance, and is suitable for small-scale production.

• Can be paired with PLA coated paper or environmentally friendly ink, in line with the environmental trends of the European, American, and Russian markets.

• The single plate paper cup forming machine is an efficient and flexible paper cup production equipment, especially suitable for small and medium-sized enterprises and startups.

Maintenance of 9 Intelligent Medium Speed Paper Cup Forming Machine should be carried out in strict compliance with the maintenance guidance.

1. Every component should be cleaned up carefully.

2. For sanitation and cleanliness, a fixed schedule should be maintained to clean and wipe the machine. Greasy dirt should be removed from the paper, die and roller. The machine must be kept from paper scraps, dust, plastic rolling, etc.

3. Glycerol can be used to lubricate the entire machine.

1. We offer a one-year warranty for the 9 Intelligent Medium Speed Paper Cup Forming Machine from the shipment date.

2. The warranty does not cover normally worn components.

3. We will not be responsible for any damage caused by misusing, improper handling, negligent maintenance, intentional injury or other damages.

• 24/7 Customer Support

Provide multi-channel (phone, live chat, email, app) instant technical support to ensure customer issues are addressed immediately.

Offer multilingual services to meet the needs of global customers.

• Priority Response Mechanism

Classify priorities based on urgency (e.g., 2-hour response for equipment breakdowns, 24-hour response for non-critical issues).

Provide remote diagnostics via IoT technology for real-time monitoring and early detection of potential issues.

• Spare Parts Supply Chain Management

Establish regional spare parts centers to ensure fast replacement of commonly used components.

Offer replacement equipment or backup machines (for critical devices) to minimize downtime losses.