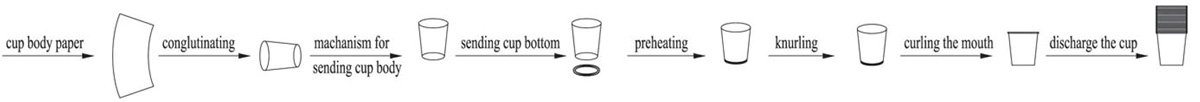

YB-S122 High-speed paper cup forming machine has the advantages of high performance,high efficiency and high quality; The overall steel plate body and the oil-draining lubrication system ensure the long-term normal and stable operation of the equipment;

Paper Cup Specification: 1.5-10 Oz

Production Speed: 120-140 pcs/min

Paper Cup Material: 150-350 g/m²

YB-S122 High-speed paper cup forming machine has the advantages of high performance,high efficiency and high quality;

The overall steel plate body and the oil-draining lubrication system ensure the long-term normal and stable operation of the equipment;

Advanced high-precision cam drive and gear transmission make each station accurate;servo motor tracking bottom feeding paper locks the size of bottom paper ,which effectively saves raw materials;

Human-machine interface PLC system controls the long-term stable operation of the whole machine;automatic counting cup collection table coordinated and reasonable setting can replace manual busy work.

|

Model |

S122 |

|

Paper Cups |

1.5oz -10oz |

|

Specifications

|

(56-450ml) (mold exchangeable) |

|

Top: 45-90mm |

|

|

Height: 30-90mm |

|

|

Bottom: 30-60mm |

|

|

Paper Specification |

150-350 GSM single/double PE coated paper |

|

Production Capacity |

120-140 pcs/min |

|

Voltage |

220V/380V 50HZ 3Phases |

|

Average Power |

14 KW |

|

Air Supply Requirement |

Air pressure:0.6-0.8 Mpa Air out-put:0.6cbm/min (Air Compressor required) |

|

Total Weight |

3500KG |

|

Dimensions |

2600x1660x2050mm |

|

Hot-air Gun System |

3sets |

• Double turntable design: The top edge roll and bottom seal are designed separately, which greatly improves the stability of the machine.

• 10 mold heads: The overall mold head uses 10 molds and is made of aluminum material. Compared with the single board, which only has 8 phenol separable materials, the finished paper cup is not easy to get dirty.

• Robot hand cup feeding device: 4-in-1 rotating manipulator cup feeding device makes the machine run more stable and faster.

• Bottom hot air heater: The double turntable adds 4 sets of hot air blowing systems, soft paper fans, and bottom paper.The bottom paper is heated twice when the machine is running at high speed, so that the quality of the finished paper cup is better and there will be no water leakage problem.

• Touch screen: Using PLC controller and touch screen (human-machine interface, all working parameters can be set on the control panel to facilitate parameter setting and adjustment. (Easy to operate).

• Bottom paper feeding and punching unit: The bottom paper feeding and punching are controlled by two servo motors,which ensures more accurate bottom paper feeding and cutting, greatly saving bottom paper.

• Bottom waste paper conveyor belt: The bottom paper will be transported through the conveyor belt and discharged.There are fewer problems with waste paper jamming on the bottom paper.

• The YB-S122 high-speed paper cup forming machine has the advantages of high performance, high efficiency, high quality and high cost performance.

• The integral steel plate body and the oil-spraying lubrication system ensure the long-term normal and stable operation of the equipment.

• Advanced high-precision CAM drive combined with gear transmission ensures precise and error-free forming at each workstation.

• The servo tracking bottom feeding locks the size of the cup bottom, effectively saving raw materials.

• An independent rolled edge plate. If it can be rolled twice, the rim of the cup will be rounder and more solid.

• It has self-diagnosis and alarm functions. When the equipment malfunctions, it can promptly and accurately display the fault information, facilitating maintenance personnel to quickly locate and eliminate the fault, thereby reducing the maintenance time and cost of the equipment.

• Use a plc programmable logic controller. High reliability and simple programming. Strong flexibility. Powerful functions and low maintenance cost. Good data processing ability.

• It can produce both cold and hot paper cups. It is widely applied in the catering industry.

• This YB-S122 small double-disc paper cup forming machine is a cost-effective machine developed by our company in response to the market for the 2oz-10oz small cup type.

Maintenance of S122 High Speed Paper Cup Forming Machine should be carried out in strict compliance with the maintenance guidance.

1. Every component should be cleaned up carefully.

2. For sanitation and cleanliness, a fixed schedule should be maintained to clean and wipe the machine. Greasy dirt should be removed from the paper, die and roller. The machine must be kept from paper scraps, dust, plastic rolling, etc.

3. Glycerol can be used to lubricate the entire machine.

1. We offer a one-year warranty for the S122 High Speed Paper Cup Forming Machine from the shipment date.

2. The warranty does not cover normally worn components.

3. We will not be responsible for any damage caused by misusing, improper handling, negligent maintenance, intentional injury or other damages.

• 24/7 Customer Support

Provide multi-channel (phone, live chat, email, app) instant technical support to ensure customer issues are addressed immediately.

Offer multilingual services to meet the needs of global customers.

• Priority Response Mechanism

Classify priorities based on urgency (e.g., 2-hour response for equipment breakdowns, 24-hour response for non-critical issues).

Provide remote diagnostics via IoT technology for real-time monitoring and early detection of potential issues.

• Spare Parts Supply Chain Management

Establish regional spare parts centers to ensure fast replacement of commonly used components.

Offer replacement equipment or backup machines (for critical devices) to minimize downtime losses.